What Imprint Methods Are Used to Print Your Logo on Products at Crestline?

Definitions of Imprint Methods for Promotional Products

What are 1-Color, 2-Color & 3-Color Printing?

One color printing involves using a single solid ink color to imprint your logo or artwork onto various promotional items. This is done through the spot color printing process, where each color is applied individually—though in this case, only one color is used. It’s the most popular option because it’s also the most cost-effective and because it makes it easy to create a simple, high contrast design.

Commonly used on: Pens and other small items

Two color printing utilizes the spot color process to apply two different ink colors to your custom imprinted product. Each ink color is transferred separately, ensuring a clean and precise look without any blending.

Commonly used on: Table throws and swag with medium to large imprint area.

Three color printing also employs the spot color process to apply three distinct ink colors to your custom imprinted product. This method allows for more complex designs while maintaining clarity and sharpness.

What is Full-Color or 4-Color Process Printing?

Full color printing, also known as four color process, digital, or CMYK printing, uses a digital printer to apply a logo design onto promotional items in a full spectrum of colors. This method allows for shading, gradients, and color blending, unlike one or two color printing which use individual spot colors.

Referred to as 4 color process or CMYK printing, this technique prints four color shades (cyan, magenta, yellow, and black) simultaneously using a digital printer. This process accurately recreates a customer’s logo or artwork on their chosen products. Full color printing is also called digital printing due to the use of digital printers to produce highly detailed and photographic designs on promotional items. As digital printing has become more efficient, full color printing is often as affordable as two-color spot printing, making it an increasingly popular choice.

Commonly used on: Stickers & decals, banners, drinkware, trade show displays and for any design involving a photo or gradient

What is Foil Stamping?

Foil stamping is a specialized printing technique used to enhance the visual appeal of promotional products. This process involves applying a thin layer of metallic or pigmented foil onto the surface of an item using heat and pressure. A heated metal die is used to transfer the foil onto the product, creating a precise and durable imprint. The result is a shiny, textured, and eye-catching design that can add a touch of elegance and sophistication to various materials.

Commonly used on: folders, padfolios, certificate holders & boutique or gift bags

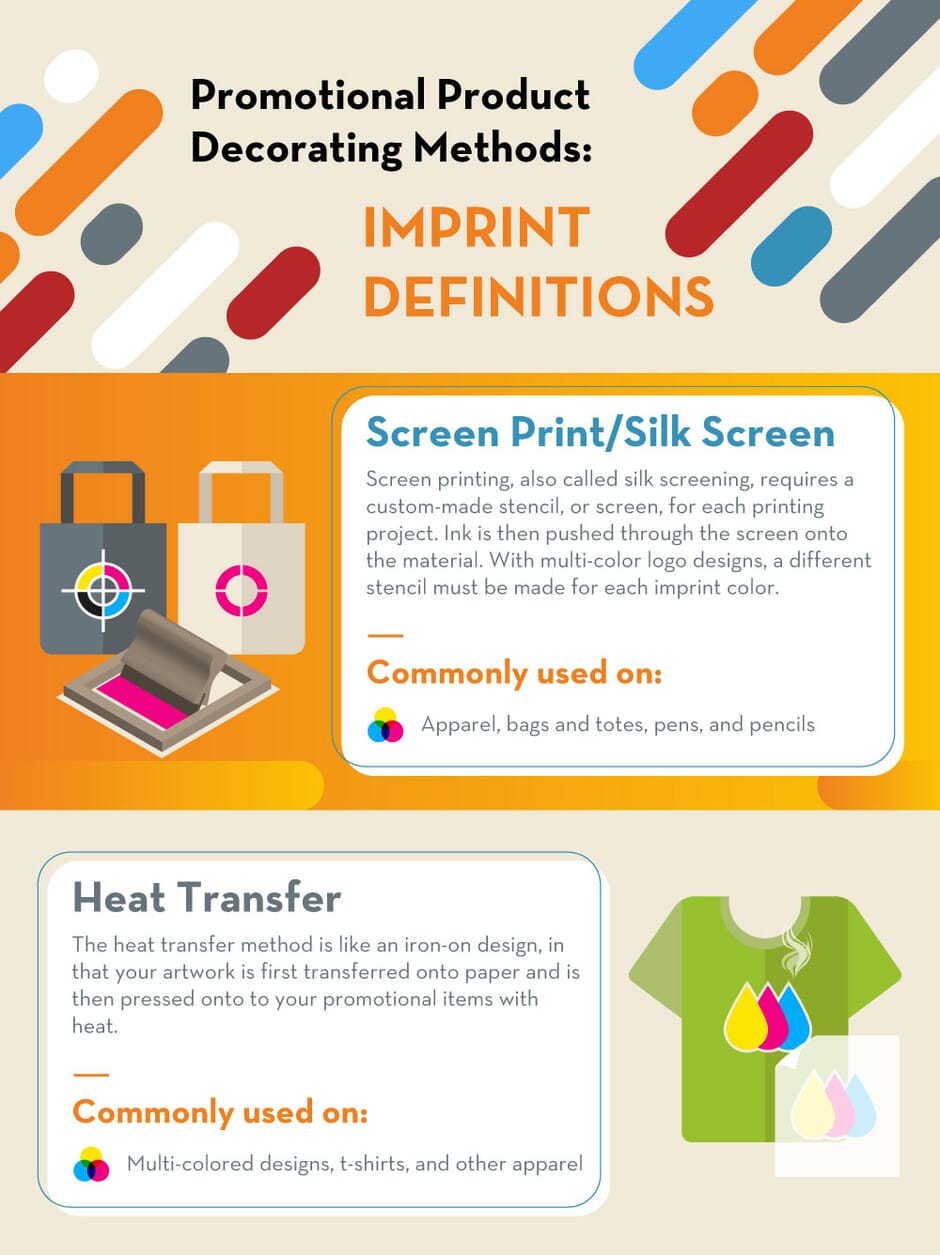

What is Screen Print (Silk Screen)?

Screen printing, also called silk screening, requires a custom-made stencil, or screen, for each printing project. Ink is then pushed through the screen onto the material. For multi-color logo designs, a different stencil must be made for each imprint color to print your logo on products.

Commonly used on: Apparel, bags and totes, and pens and pencils

What is Heat Transfer?

The heat transfer method is like an iron-on design, in that your artwork is first transferred onto paper and then pressed onto your promotional items with heat.

Commonly used on: Multi-color designs, t-shirts, and other apparel

What is Pad Printing?

What is Debossing & Embossing?

Debossing and embossing use a metal die to create a raised or indented logo design on your product of choice. Embossing creates a 3D, raised logo design, while debossing creates an indented logo design.

Commonly used on: Leather and faux leather products, folders, and portfolios and padfolios

What is Laser Engraving?

Just like its name, laser engraving uses a laser beam to etch your custom design onto your promotional items. Laser engraving does not use ink and does not result in a colored logo, but is a very durable and long-lasting way to print your logo on products.

Commonly used on: Products made of metal and wood, pens, mugs, and tumblers

What is Embroidery?

Embroidered logos are created by first making a custom pattern that is then uploaded onto a computer. Next, a machine stitches your design onto the promo items. Each logo color is stitched onto the items individually until the final design is achieved.

Commonly used on: Apparel, towels, and blankets

What is Dye Sublimation?

Dye sublimation is a full-color imprint method where artwork is digitally printed onto a transfer material. The artwork is then transferred using heat from the material into the fabric of the promo products. Dye sublimation allows vibrant, photo-quality imprints to be achieved.

Commonly used on: Table covers, lanyards, face masks, and Koozies®/can coolers.